In an era where our lives revolve around electronic devices, a dwindling battery is a constant, anxiety-inducing presence. That's where the battery monitor steps in, acting as your personal guardian to ensure you never fall victim to unexpected power outages again.

Table of Content

What is a Battery Monitor?

A battery monitor is a powerful tool that tracks, analyzes, and provides real-time information about a device's battery performance and health. It helps users manage and optimize battery life by offering insights, alerts, and recommendations for extending battery performance. Moreover, battery monitors ensure efficient charging by preventing overcharging and maximizing battery longevity. In addition to indicating the state of charge, battery monitors collect and display valuable information like battery voltage, power consumption, estimated remaining runtime, current consumption, and battery temperature. This comprehensive data allows users to gain a deeper understanding of their battery's performance and make informed decisions to enhance overall battery usage.

How Does A Battery Monitor Work?

A battery monitor works by measuring various parameters of a battery to provide information about its status and performance. There are primarily two types of battery monitors: shunt-based and voltage-based.

1.Shunt-based battery monitors

Shunt-based monitors use a shunt resistor placed in series with the battery to measure the current flowing through it. The voltage drop across this resistor is proportional to the current, allowing the monitor to calculate the current consumption of the battery. By integrating the current over time, the monitor can determine the state of charge (SOC) and estimate the remaining battery capacity.

Shunt-based monitors can also measure other parameters like battery voltage and temperature. By combining these measurements with the current information, they provide a comprehensive view of the battery's health and performance. Shunt-based monitors are commonly used in applications where precise current measurement is required, such as electric vehicles and renewable energy systems.

2.Voltage-based battery monitors

Voltage-based monitors rely on the battery's terminal voltage to estimate its state of charge and capacity. They use voltage measurements against a pre-determined voltage vs. SOC curve to determine the current battery level. These monitors are simpler and less expensive compared to shunt-based monitors but may sacrifice some accuracy in the process.

Voltage-based monitors are commonly found in consumer electronic devices like smartphones, laptops, and tablets. They are also widely used in automotive applications. While they may not provide as precise measurements as shunt-based monitors, they still offer useful information about battery levels and can prevent overcharging or excessive discharge.

Both shunt-based and voltage-based monitors have their advantages and limitations, so choosing the right one depends on the specific requirements of the application.

Why You Need a Battery Monitor

Battery monitors are essential tools for managing and optimizing battery life. They provide valuable information about battery status and health, allowing you to make informed decisions to optimize battery performance, adjust settings, implement power-saving practices, or replace aging batteries. Here are some reasons why you need a battery monitor:

- Battery Health Monitoring: A battery monitor allows you to track the health of your battery over time. It provides information about the state of charge (SOC), state of health (SOH), and remaining capacity of the battery. This helps you identify if your battery is degrading or losing capacity, allowing you to take appropriate actions like calibration or replacement.

- Optimization of Battery Performance: By monitoring battery voltage, current, and temperature, you can better understand how your battery is performing under different conditions. This information helps you optimize battery usage, adjust power settings, and implement practices that extend battery life.

- Precise Current Measurement: Shunt-based battery monitors use a shunt resistor to measure the current flowing through the battery. This provides accurate current consumption information, which is crucial in applications where precise current measurement is needed, such as electric vehicles or energy storage systems.

- Predictive Maintenance: A battery monitor can detect early signs of battery failure or degradation. By monitoring parameters like voltage, temperature, and charge-discharge cycles, you can anticipate potential issues and take corrective actions before they lead to a battery failure or unexpected downtime.

- Real-time Monitoring and Alarms: Battery monitors offer real-time monitoring of battery parameters, allowing you to track the battery's performance and health. They can trigger alarms or notifications if parameters exceed predefined thresholds, enabling you to take immediate action and prevent any potential damage or system failure.

Overall, a battery monitor provides essential information to help you manage your batteries effectively, extend their lifespan, and optimize their performance. Whether you are using batteries in consumer electronics, automotive systems, renewable energy systems, or any other application, a battery monitor is a valuable tool for maintaining and maximizing battery life.

Example of Battery Monitor

An illustration of the importance of battery monitors can be seen in the decision-making process of switching the fridge in an RV from battery power to propane. For instance, in the early evening, if the battery monitor indicates four more hours of runtime, switching to propane could eliminate the need to run a generator throughout the night.

When using lead-acid batteries, it is crucial to avoid draining them beyond 50 percent state of charge for optimal longevity. Using an accurate shunt-based monitor enables users to identify when they are nearing the 50% threshold and need to be recharged. Since lead-acid batteries have a lengthy charging process that requires completing an absorption cycle, not knowing when they reach full charge without a battery monitor could result in a shortened lifespan if they are discharged prematurely.

Upgrading the lead-acid battery to lithium batteries can solve the probelm, however a battery monitor remains crucial for monitoring remaining energy levels or the amount of charge in the batteries.

Battery Monitor Vs. Battery Management System (BMS)

Battery monitors and battery management systems (BMS) play distinct but interconnected roles in managing and optimizing battery performance.

As previously discussed, battery monitors are primarily responsible for monitoring various battery parameters, including voltage, current, state of charge, and capacity. They provide valuable information about the battery's health and performance, enabling users to make informed decisions regarding battery usage, maintenance, and energy-saving practices. Battery monitors can be particularly useful in applications that require precise current measurement.

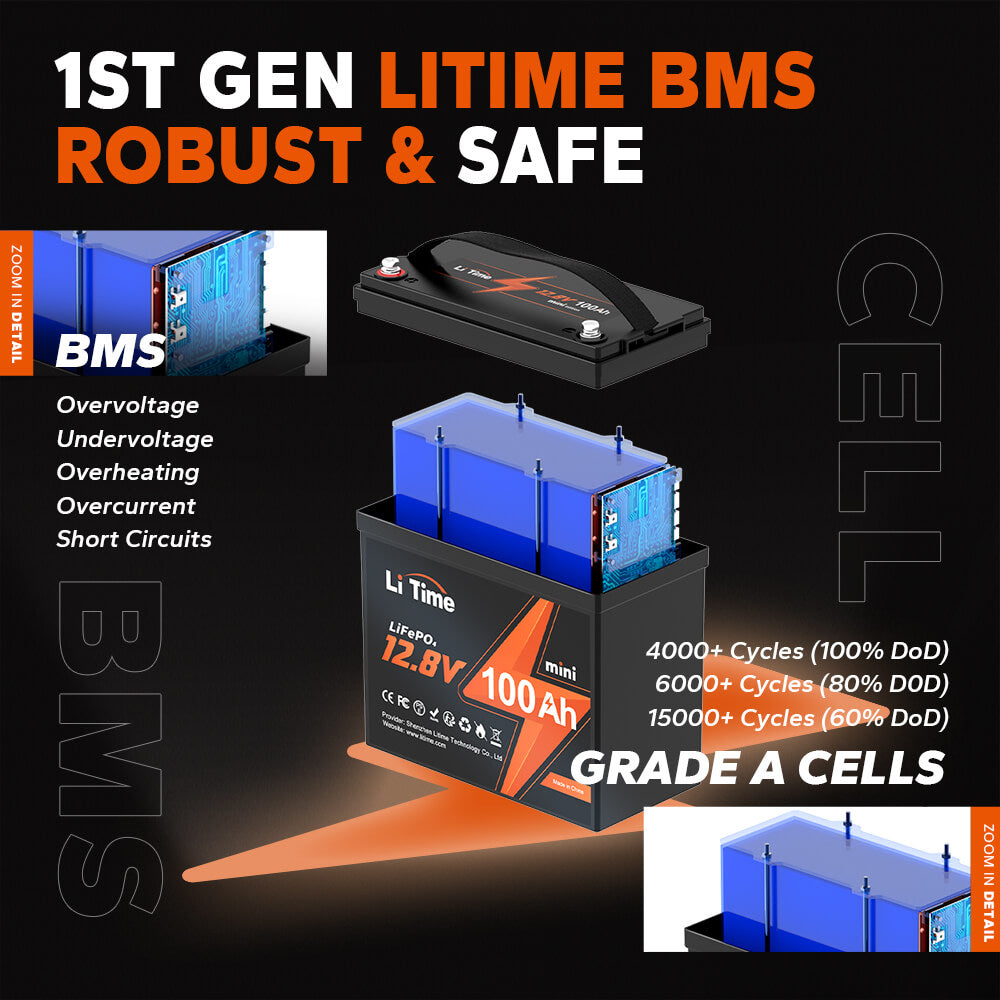

On the other hand, a battery management system (BMS) encompasses a broader range of functionalities. In addition to monitoring battery parameters, BMSs actively manage the battery to ensure safe and efficient operation. This includes tasks such as cell balancing, temperature monitoring, protection circuitry, and communication interfaces. BMSs are commonly integrated into lithium batteries themselves, whereas battery monitors are typically separate entities that need to be externally connected.

The difference between a battery monitor and a BMS lies in their core functions. While a battery monitor focuses on monitoring and gathering data about the battery, a BMS takes that data and actively manages the battery to optimize its performance and protect it from potential dangers.

Battery Monitor Recommended: LiTime 500A Battery Monitor With Shunt

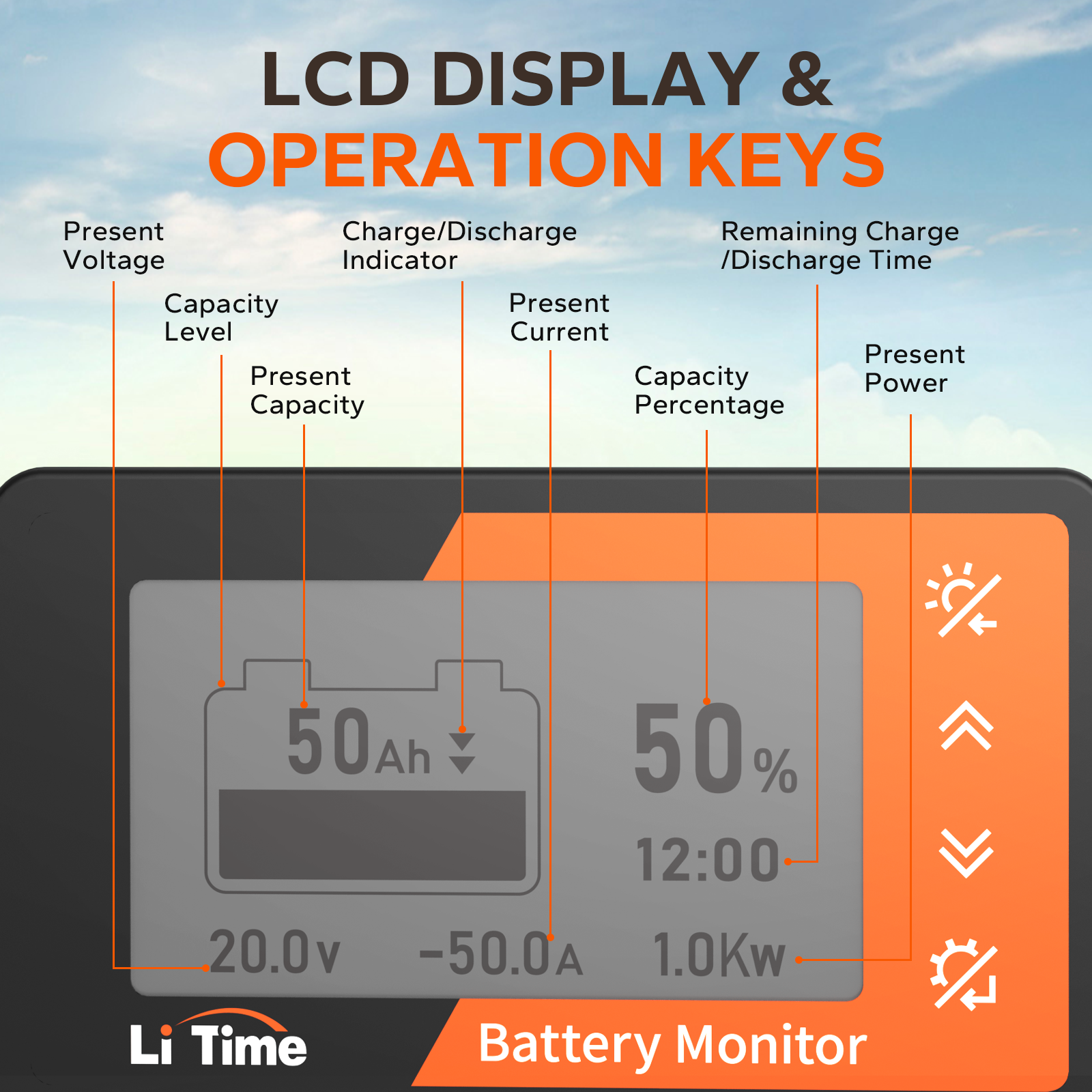

The LiTime 500A Battery Monitor with Shunt - a versatile solution designed to optimize battery performance. This battery monitor is suitable for battery banks ranging from 8 to 120V and offers auto-recognition for various battery types, including Li-ion, LiFePO4, Gel, AGM, and more. With its comprehensive display, the LiTime 500A provides valuable information about battery voltage, current, power, and capacity. It also offers insights into remaining charge/discharge time, charge/discharge indicators, and capacity percentage. The display features a convenient backlight for easy visibility even in low-light conditions, making it exceptionally user-friendly.

Installation of the LiTime 500A Battery Monitor is hassle-free. The shunt can be stably placed or mounted on a flat surface using the shunt holder. The monitor display itself is easily installed using tabs, and the manual provides detailed instructions for a seamless setup process.

To ensure the utmost safety and awareness, the LiTime 500A incorporates alarms and notifications. If the voltage or capacity falls below the set value, the LCD display will flash, and the built-in buzzer will sound an alarm every 10 seconds. This feature ensures timely alerts, enabling proactive measures to be taken.

Step By Step Guide on How To Install LiTime 500A Battery Monitor

Section 1: Mounting

1. Shunt

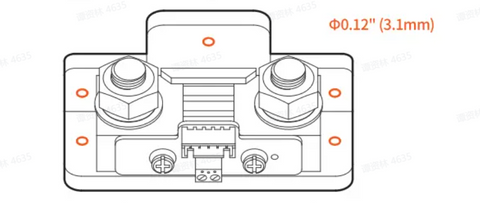

The shunt can be stably placed or mounted on a flat surface by the shunt holder. There’re five Φ0.12″(3.1mm) holes for mounting purposes located in the holder that can be screwed onto the flat surface with the provides screws.

2.Monitor Screen

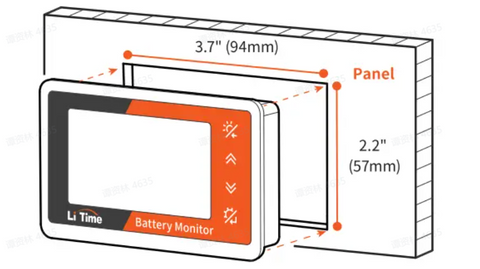

The monitor screen is simple to install as it’s fixed by tabs. Cut a 3.7″*2.2″(94mm*57mm) rectangular opening in the panel according to the dimensions. Then put the monitor screen into the opening, and make sure that the tabs are locked.

Section 2: CONNECTION

Prepare for Setup Before Connection

Before connecting, fully charge the battery/battery system, test and record its resting voltage, and prepare for the setup after the connection is completed.

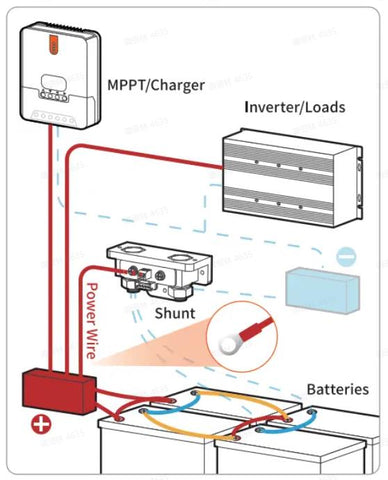

Basic Connection for Single Battery/ Series-only Battery Bank

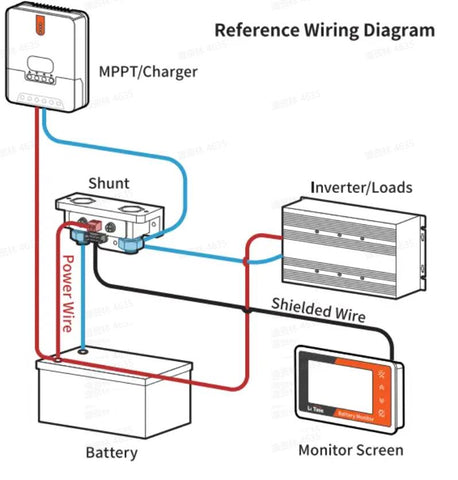

Refer to the following wiring diagram and wiring steps to complete the connection of a single battery or a series-only battery system.

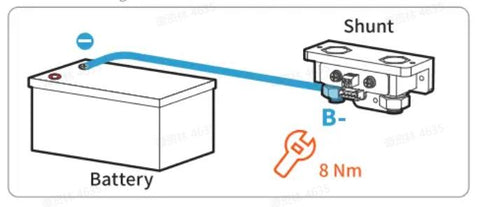

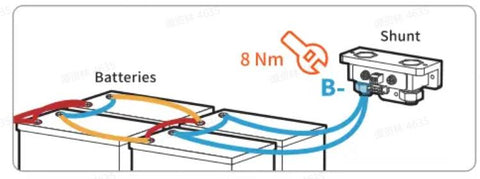

Step 1: Connect the - terminal of the battery to the M10 bolt on the “B-” side of the shunt. Tighten the nut to the bolts under the 8~12Nm setting.

Note: There should be no other connections on this side (B-) of the shunt or on the - terminal of the battery. Any load or charger connected here will be excluded from the battery state of charge calculation.

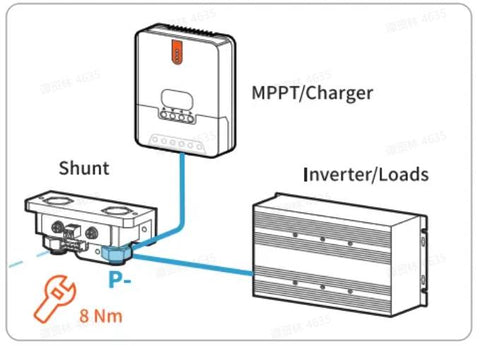

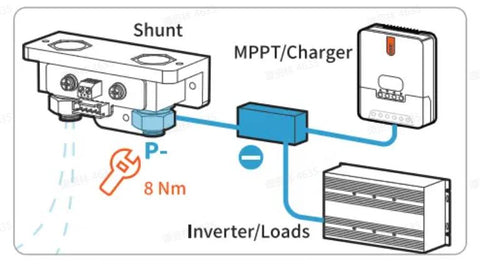

Step 2: Connect the - terminal of the electrical system to the M10 bolt on the “P-” side of the shunt. Tighten the nut to the bolts under the 8~12Nm settings.

Note: Make sure that the - of all DC loads, inverters, battery chargers, solar chargers, and other charger sources are connected “after” the shunt (not directly connected to the battery), and that all current flowing in/out the battery passes through the shunt.

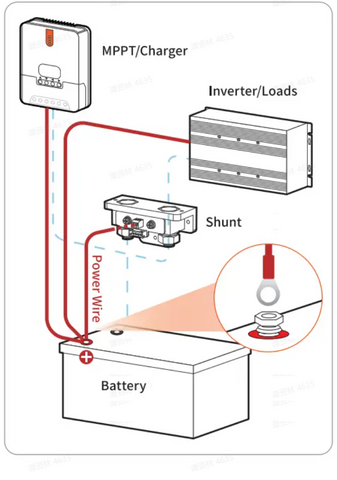

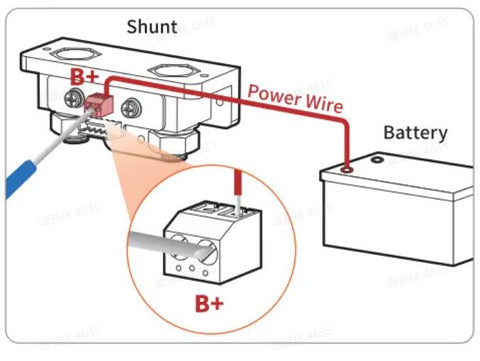

Step 3: Connect the + terminals of the electrical system and the M8 ring terminal of the power wire to the + terminal of the battery.

Step 4: Unscrew the B+ terminal on the shunt with the screw-driver provided, connect the ferrule pin of the power wire to the B+ terminal, and tighten it again.

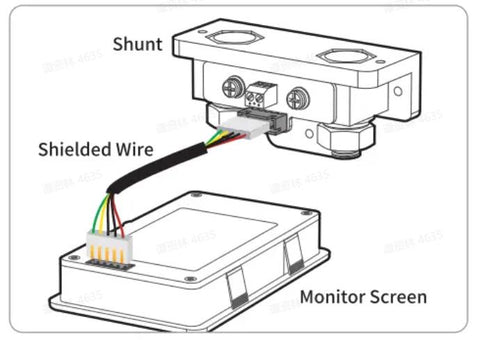

Step 5: Connect the shunt to the monitor screen by the shielded wire. And the LCD display should turn on assuming proper connection.

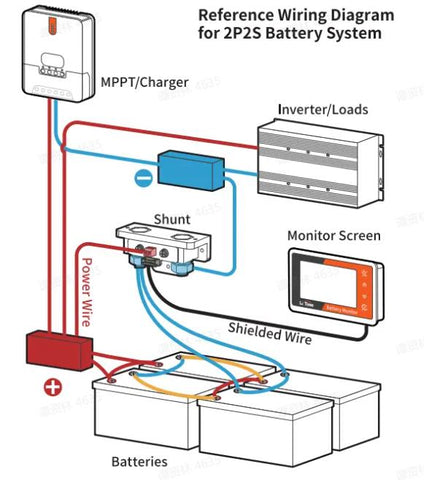

Connection for Parallel/ Series & Parallel Battery Bank

If a parallel or series-parallel battery bank needs to be monitored, it is recommended to use two bus bars for the total positive and total negative output/input connections of the battery bank.

Step 1: Complete the parallel/series-parallel connection between batteries (recommended to connect in parallel first and then in series).

Step 2: Connect all - input/output terminals of the battery bank to the M10 bolt on the “B-” side of the shunt. Tighten the nut to the bolts under the 8~12Nm settings.

Note: There should be no other connections on this side (B-) of the shunt or the - battery terminal. Any load or charger connected here will be excluded from the battery state of charge calculation.

Step 3: Connect the M10 bolt on the “P-” side of the shunt to the - bus bar. Tighten the nut to the bolts under the 8~12Nm setting.

And then connect the - terminals of the electrical system to the - bus bar.

Note: Make sure that the - of all DC loads, inverters, battery chargers, solar chargers, and other charge sources are connected “after” the shunt (only directly connected to the battery), and that all current flowing in/out the battery passes through the shunt.

Step 4: Connect the below terminals to the positive bus bar.

- All + input/output terminals of the battery bank

- + terminals of the electrical system

- M8 ring terminal of the power wire

Conclusion

Having accurate information about your battery system is crucial for making informed decisions to maximize its performance. If you want to optimize the usage of your battery system, investing in a battery monitor is a smart choice. It is a cost-effective and valuable upgrade that provides you with important insights and helps you get the most out of your batteries.